As our Doug Colbeth, our CEO, wrote recently

Companies must look at their supply chains as having a “cause and effect” relationship with other key parts of their business. It is in the supply chain and its related areas where companies can effectively address the three key challenges of any business; financial performance, customer satisfaction, and corporate risk.

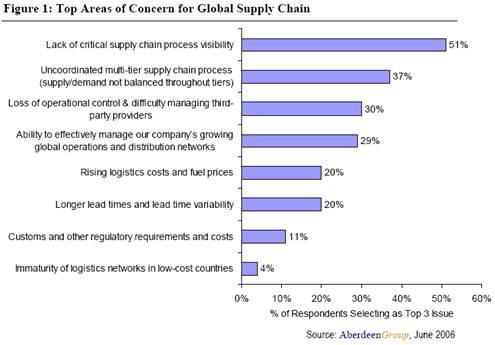

There are several key points in Doug’s statement, but the one I want to highlight is the cause and effect relationship to other key parts of business. While gaining control of one’s own operations is important, in today’s outsourced supply chain, the cause and effect relationship often spans across multiple tiers. This multi-tier cause and effect relationship is fairly well described and explained through concepts such as supply chain visibility, and remains an issue for many multi-national organizations, let alone multi-tier supply chains. Over five years ago, Aberdeen Group in a Benchmark report titled, “Industry Priorities for Visibility, B2B Collaboration, Trade Compliance, and Risk Management” identified many of these issues. As late as February 2011, Aberdeen Group published another report titled “Supply Chain Visibility Excellence” in which the greatest pressure to improve supply chain visibility is “Growing global operations/complexity”. It ain’t goin’ away any time soon.

But Doug is making a different point (I think). My interpretation of Doug’s comment is that a company’s operations functions have to operate in a coordinated or orchestrated fashion in order to drive the best financial performance. While most of our focus is in manufacturing, where the issue is perhaps most acute, many other sectors can benefit from Doug’s advice. As an example of the need for orchestration between functions, how many project management systems provide a mechanism to plan materials in conjunction with resource assignment and task dependencies? And yet in many engineer-to-order (ETO) environments payment is based upon milestone achievement so any slippage because of material shortage has a big impact on the top line. And of course on the bottom line too because while resources can be assigned new tasks, there is always lost productivity when they are reassigned. And of course it isn’t that no orchestration between functions happens today, it’s just that very little of it is fact based and there is no opportunity to perform what-if analysis of different scenarios to evaluate the impact on financial performance, customer satisfaction, and operational risk. So what is orchestration? Jane Barrett of Gartner wrote in a Supply Chain Brain article titled “The Secret Sauce to Supply Chain Orchestration” that:

Orchestration describes a value-driven organization that is consciously excellent. This ability to make conscious choices and to understand the trade-offs comes from advanced capabilities in information management, demand sensing and shaping, cost-to-serve analysis, end-to-end segmentation, simulation and analytics. It requires strong collaboration internally and externally.

The on-line Merriam-Webster dictionary defines “orchestrate” as:

or·ches·trate

1 . a) to compose or arrange (music) for an orchestra

b) to provide with orchestration <orchestrate a ballet>

2. to arrange or combine so as to achieve a desired or maximum effect

While clearly it is the second definition that is more directly relevant to the supply chain, or operations more broadly, we should not lose sight of the idiomatic value of the first definition. A lot of the value of a control tower comes from being able to ‘arrange’ the processes and people in a harmonious whole. The beauty of an orchestra or rock band comes from the manner in which the different instruments are played collectively. If any one part of the orchestra is out of tune or playing too loudly/quietly the sound of the entire orchestra is affected, not just of that instrument section. In order to do this, every orchestra must have a conductor. Undoubtedly the orchestra could get through the piece without a conductor, but they do so with far less effort and with a superior outcome if they do use a conductor. Key aspects of the conductor’s role is to interpret the piece, keep each section playing in time, and to ensure the correct sound balance across sections. A control tower is equivalent to the conductor in operations orchestration, which ensures that all the functions are operating in harmony. This is what Doug is referring to in his blog: Making sure that not only are the functions sharing information, but that they are operating in unison to achieve common goals. And this is where Jane Barrett’s capabilities of simulation and analytics come into play. While undoubtedly on concert night the orchestra needs to play flawlessly by following the conductors lead, it is the practice sessions in which the conductor will have experimented, sometimes with individual sections of the orchestra, and even during the dress rehearsal. This experimentation is vital for the conductor to achieve the right sound. Without the equivalent "what-if" capabilities in supply chain, and operations more generally, it is extremely difficult to gain actionable insights and to reduce corporate risk. Without a doubt cross-functional visibility, formal meetings, and standard reports are foundational requirements, the real value to operations is the ability to evaluate alternative scenarios quickly and collaboratively.

Additional Resources

- Supply chain control tower frequently asked questions

Discussions

Leave a Reply