Trevor Miles and I have been having a healthy discussion on the Internet of Things and how these technology changes are shaping the way we work.

- Part 1: SMAC in the Middle of Supply Chain Change

- Part 2: Will the Internet of Things (IoT) Help Eliminate Information Latency and Deficiency in Supply Planning?

- Part 3: SMAC in the Middle of Supply Chain Change

This is part 4 in our Internet of Things Series: The Supply Chain “Change” dilemma!

A few weeks ago, Charles Wehlage wrote a blog post on his take on The Innovators Dilemma. I thought his analogies with supply chain strategy and execution were spot on. In this piece, Clayton Christensen specifically focused on why organizations fail. And not just any organization, but the great ones! The key learning is that the individuals who as a team have just witnessed a big win as a result of a hard worked strategy are highly likely to miss the budding wave of disruptive forces and be ready for the next change. My own experiences wit

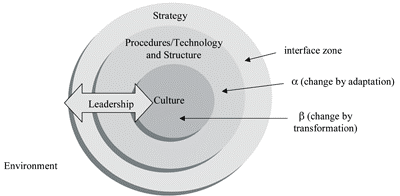

h different large scale transformations certainly point to this valid the hypothesis. An organization’s capability to sustain its innovative streak is largely dependent on the organizational “software” a.k.a. human resource + DNA. Therefore, the dilemma is how to synchronize the “social dynamics” within an organization and lead continuous change as digital technologies evolve and their adoption is a necessity. The graphic from Svyantek and DeShon’s thoughts on “System interface and hierarchy of efforts required for change in an organization” illustrates the complexity of change. Organizational software comes before process and technology. I equate corporates especially the supply chain organizations with living organisms. They evolve as new scenarios emerge, oil prices fluctuate, new suppliers are added, customers are acquired, new markets penetrated and more data and information becomes available. It is wrong to assume that the collective intelligence of a thinking group can be subsumed in the so-perceived “automated Internet of Things (IoT)” world. Also, pushing the organizational supply chain change issues to a set of mere “team building” workshops will not suffice either. Information flow within an organization plays a critical role in creating a culture of transparency, commitment to shared goals and observable leadership behaviors. The microcosm of the organization is thus formed within each cell of the organization. The information flow through these cells or nodes spread out within and outside the organization’s supply network shall determine the sustainability of change. Can we leverage the IoT paradigm to create a different organizational culture? For most global organizations, the supply chain as a system can perhaps be best characterized as geographically spread but comprising of interdependent elements guided and orchestrated by thousands of brains. Arguably, these supply chains are highly complex and difficult to change. As technologies provide new opportunities for disruptive innovation, building a “learning organization”- along the lines of the model proposed by Peter Senge- could perhaps help in not getting caught in its own success. According to Senge:'learning organizations' are those organizations where people continually expand their capacity to create the results they truly desire, where new and expansive patterns of thinking are nurtured, where collective aspiration is set free, and where people are continually learning to see the whole together."

He argues that only those organizations that are able to adapt quickly and effectively will be able to excel in their field or market. So, when Trevor and I started discussing the impact of Internet of Things on the Supply Chain; it soon became clear that we are looking at a massive opportunity for transformation. The path to realization will require balancing the communication, computing and control with human intervention on one hand and building a continuously learning organization on the other. What are your thoughts on this matter? Comment and let us know.

Leave a Reply